Words by Julian Thrasher, Cytech trainer and master technician.

The cycle workshop can be a hectic place at times (or all the time if you’re lucky!). The spirit of this piece is to show some of the things technicians may do in order to increase the accuracy and speed of repairs and therefore the productivity of the workshop, so when we say ‘hack’ we mean it in the professional sense. Here are my five top ‘hacks’ to make your workshop life that little bit easier:

1. The internal spoke nipple trick

Dropping a spoke nipple into the internal walls of the rim is one of the most frustrating things you can do – especially on a deep section carbon wheel. This can be avoided by creating your own spoke nipple holder. All you’ll need is an old spoke (with a decent thread) and a spoke nipple. Put the spoke nipple onto the spoke the wrong way round and tighten it to the end of the threads (clamping the spoke in a vice and tightening the nipple with a spoke key is a good idea) This will leave you with about 3mm of thread showing from the end of the spoke – which you can use to screw the nipple you intend to use onto. The nipple is then secured in place allowing you to thread it hassle free through the rim and onto the spoke. No more rattling wheels!

2. The tubeless seating trick

If you can, remove the valve core from the valve. Doing so will allow a greater volume of air to flow in from the track pump, really useful if you don’t have a compressor and are trying to frantically pump the air in using a standard track pump. Install the tubeless tyre onto the rim and lubricate between the bead of the tyre and the rim hook with soapy water. You can use sealant and I personally find this gives an additional seal, but you will need to scrub the sealant from the tyre bead and rim hook the next time you remove the tyre. Lubricating the tyre and rim stops the rubber from sticking and allows it to slip into place at much lower pressures. The tyre should seat around the 20 PSI mark.

3. Set V-brakes to feel the same EVERY time

This one is a simple one but if every mechanic does this in the workshop then all V-braked bikes will leave the workshop feeling the same and the customer won’t struggle to undo them. Unclip the centering springs and place the noodle so that the very end rests on the tip of the cradle. Pull the cable tight so that the pads stop the wheel from turning and secure the cable fixing bolt. Push the noodle down so that it rests correctly in the cradle. This trick works because it presets exactly the same distance every time.

4. SRAM brakes – just the lever

Now if you try this and the fluid that comes out of the lever is severely discoloured then you have no option but to flush the system and do a full bleed. Sorry.

BUT – for those people who stay on top of the service intervals (i.e every six months, not years) then this is a good trick to halve the time it takes to do a SRAM brake bleed as you are only going to bleed the lever not the full system. This works because air rises, so the theory is that most of the air will accumulate in the lever making it easier to remove.

Take out the wheel and pad, put a bleed block in and remember to de-gas the fluid in the syringe thoroughly first and that the lever reach is set out far enough to give a good volume inside the lever body. Press down on the syringe and hold the pressure on (gently!) then flick the tip of the lever (pressing it in and allowing it to slip off the end of your finger is the best way). This shocks any air out that may be hiding in the lever body. Then pull up on the syringe to suck those bubbles out of the lever.

RELATED: Why Women Could Save Your Bike Shop

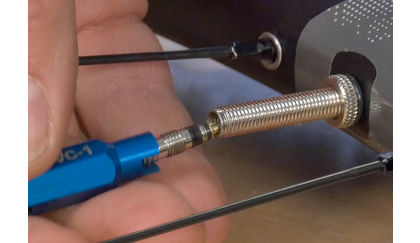

5. The bolt through truing stand trick stand

Now there is a dedicated adaptor for mounting bolt through axles into a truing stand but we’ve had good luck with the humble Hex key. A 10mm Hex key slid through the bolt through axle and then lowered into the truing stand is a quick, hassle free way to secure the wheel into a truing stand (if you don’t have the adaptors).

Want to keep updated with more bike shop tips and content?

Easy! Simply subscribe to BikeRoar's Cycling Trade Newsletter, and be sure to check out the awesome industry news from the team at CyclingIndustry.News.

RELATED ARTICLE:

Why Customer Profiling & Personalized Messaging Should Matter to Your Bike Business

Understanding and categorizing your bike shop's customers, then sending them targeted, personalized communications, is essential to staying relevant and earning their business. READ MORE

RELATED ARTICLE:

Put your business on the bike map

When a trickle of bicycle tourists passing through your city or town turns into a steady flow, how can a local business tap the opportunity? Here are a few pro-tips for getting started. READ MORE